SCM has always placed importance on surface treatment and was the first to believe in the value of having Superfici technologies for finishing as part of its range and which, thanks to the synergy between sanding and finishing processes, generate a unique advantage on the market. On the strength of its vast and consolidated know-how, the Italian company offers an extensive range of technologies for sanding, pressing and finishing, distinguishing itself as a unique partner in the entire surface treatment process: all-round products and services as well as exclusive, sought-after finishing solutions, to meet all the process and end product type requirements.

Sanding-calibrating: ‘dmc system t’ with laser engraving unit

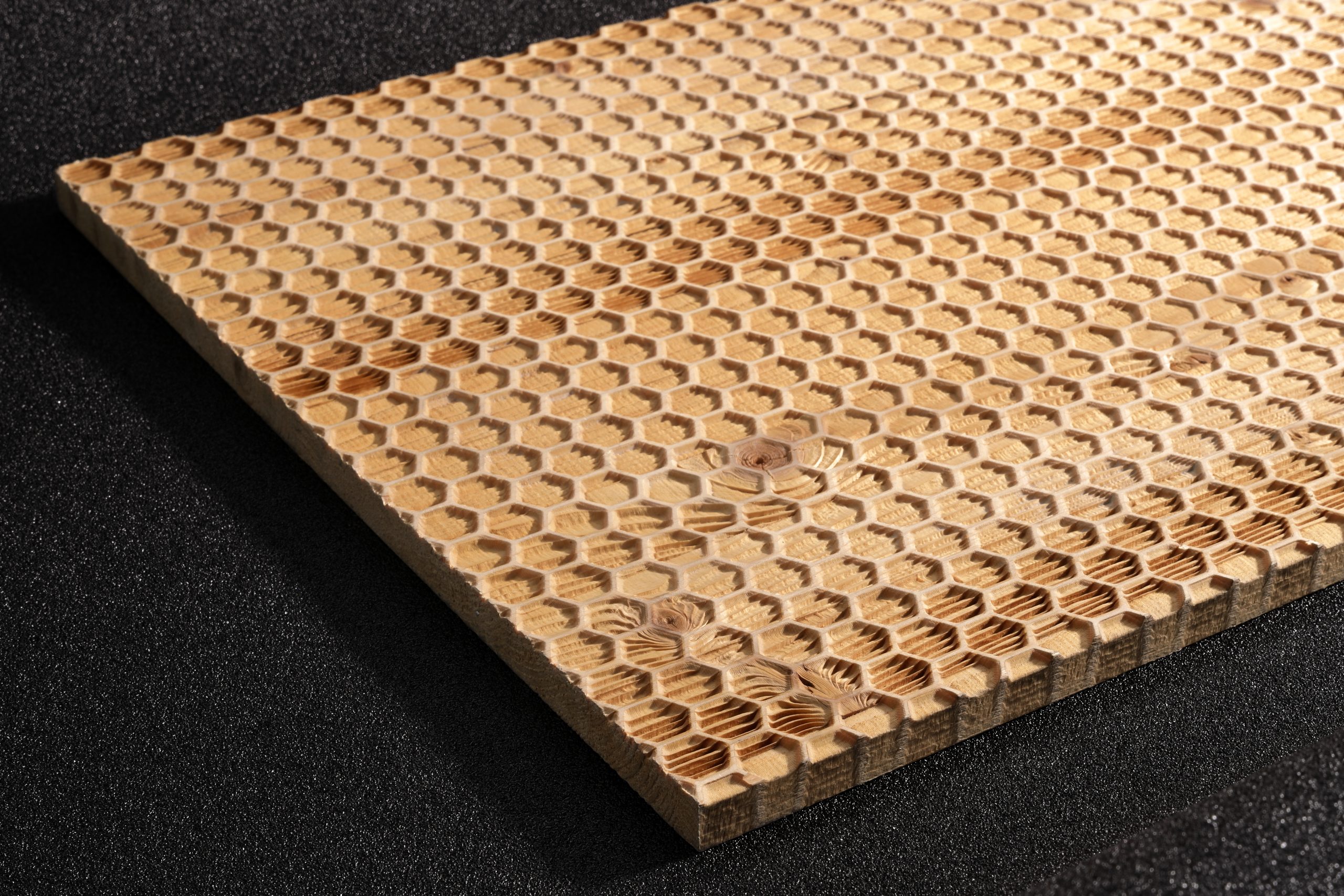

Does the market require increasingly customized finishes? The ‘dmc system t’ automatic sanding-calibrating machine, which is equipped with the exclusive CO2 laser engraving unit, offers unique customized finishing options. This machine is particularly suited for creating three-dimensional marking on parquet, wood elements, MDF panels to be ennobled, fiber cement panels and solid surfaces.

This engraving unit represents a completely new sanding technology due to the exclusive continuous passing application. The main advantages of this solution are increased productivity and the possibility to machine parts of any length: all with a truly compact solution because the Laser engraving unit, being integrated into the machine, does not increase the amount of space used.

Another important advantage comes from Self-Refilling technology, a distinctive feature of SCM’s laser engraving unit. This laser source, known as Never Ending Power, due to its unique embedded gas cylinder, ensures a continuous and automatic fresh gas refill. So the laser beam’s quality remains always at its highest level, enhancing productivity and reducing downtime. Operators can experience uninterrupted laser performance, maintaining optimal power and stability throughout their work processes.

Another benefit comes from the ‘eye-M’ PC panel with which it is possible to manage, program and set the laser working parameters, thanks to a simple and user-friendly graphic interface. With just three working parameters which can be changed, it is possible to define the useful marking level to guide the operator in an easily and intuitively way. All this with the further advantage of achieving machining monitoring in real time via webcam.

SCM laser technology has numerous applications. The wood flooring machining allows one to achieve geometrical and abstract patterns with an advancement speed of up to 3 m/min. and to also score carved surfaces thanks to a dynamic focusing system of the ray.

On the veneered effect, the SCM laser unit is particularly well suited to customizing and veneering kitchen cabinet doors. On MDF panels, relief marking before painting or plating with PVC can be achieved with the

sergiani 3d form 3D laminating press. When machining fiber cement, the laser unit is ideal for producing walls and flooring. Specifically, it allows the user to ennoble surfaces by marking abstract and/or geometric designs or replicating wood grain. When it comes to solid surfaces, it is also possible to achieve attractive veneering and customized effects on materials like Corian.

Superfici solutions for finishing: ‘compact hy’ spraying machine

Superfici ‘compact hy’ (hybrid) is suitable for medium-sized companies that require both small and large batches, while maintaining low costs. Despite its compact size, the ‘compact hy’ ensures extremely high-quality automated spraying thanks to its double spraying arm that is installed on a high precision linear guide and provides dual product application.

Flexibility is one of the main advantages of this solution. The machine is equipped with a hybrid conveyor system, which means that it is possible to work with a choice of a protective paper system or with the lacquer reclaiming system.

In its hybrid configuration, the ‘compact’ is environmentally friendly, thanks to the option of using an overspray recovery system, which helps reduce waste and maximize productivity. The double spraying arm is also housed in a booth with a dual filtration system thanks to the patented filter-on-demand system, protecting air quality and the surrounding environment.

Work planning is another advantage of this Superfici sprayer: a color touch-screen panel is integrated with our simple and intuitive software, which has the ability to set working parameters, memorize recallable recipes, diagnostics and periodic maintenance programming. With the ‘compact hy’, maintenance becomes easier: full-size doors access the cabin from both sides for easy cleaning and maintenance operations.